The LatticeAx is a fast, accurate, and low-cost cleaving solution that is perfected for all kinds of labs. It is designed and perfected as a precision cleaver that easily fits in the hand palm. It has a small footprint of 4″ cube, 100mm.

The process and patent pending AX are modeled to help the users cleave site-specific targets. It also assists strips, wafers, or précised sized sample pieces with localized targets. The LatticeAx guarantees to revolutionize the workflow for its most efficient and smallest silicon wafer cleaving tool.

The LatticeAx process and features optimizing the manual cleaving technique’s basic element. It overcomes the disadvantages of manual cleaving like repeatability and lack of accuracy. The machine is assisted by the hybrid cleaving tool that separates the gap between fully automated cleaving and manual scribing.

The success rate is increased to a great extent while making sure to keep the cost as low as possible. All it requires is a little training and then one can be an expert in using the cleaving tool. It hardly takes minutes or a day to learn all the best features of the tool.

Table of Contents

New Way of Cleaving – LatticeAx

The LatticeAx is one of the best and innovative products of Lattice Gear. It is designed differently from manual cleaving because of the following reasons.

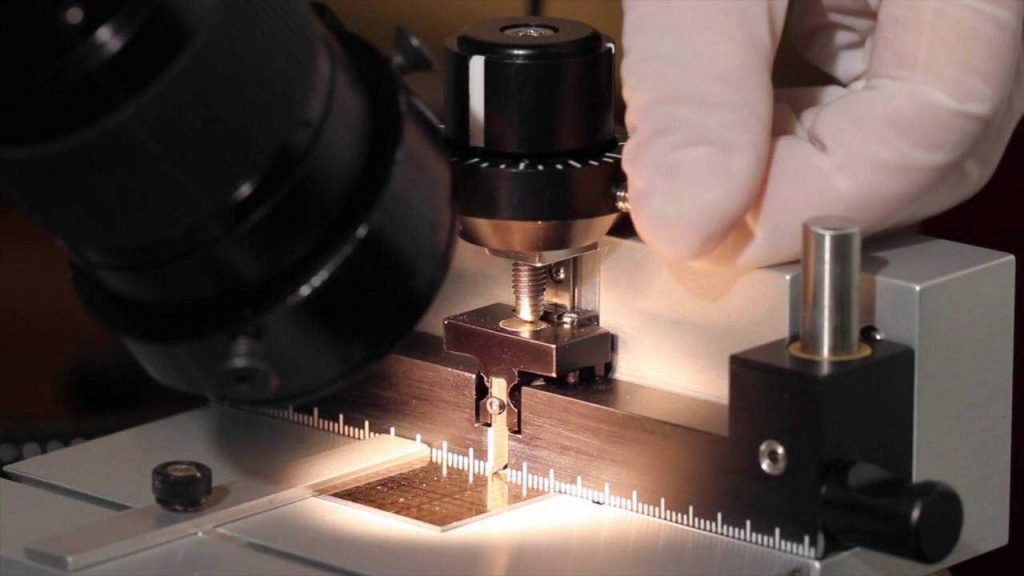

- The human vision is replaced by a high magnified digital microscope so that the target is selected precisely

- Hand coordination is replaced with précised positioning knobs. This makes it a repeatable process that does not depend on the user

- An indent is produced on the surface as a shallow depth

- A controlled slow cleave is employed following a crystal plane than breaking along the scribed line.

The hybrid cleaving tool is machine-assisted bridging the gap between the sully automated cleaving and manual scribing. The success rate is improved to a great extent and at the same time keeping the cost minimal. The cleaving process with the aid of LatticeAx 225 and 420 by LatticeGear is one of the best tools that make the entire process fast, repeatable and clean.

Although the manual cleave and scribe are fast, the result is not accurate and repeatable. There are chances for the accuracy level to be improved if the sample is viewed with the help of a stereoscope. In both, the case, the quality, and targeted accuracy will vary by its user.

Back in the days, automated micro-cleaving tools played a great role in improving the sample quality and targeted accuracy that was needed for a high-resolution image of SEM. The improvements are followed by the requirements of strict pre-preparation, inability in handling thin and small samples, lower throughput, and high cost when compared to manual cleaving.

This is not the case in the LatticeAx where it processes and features the basic elements of the manual cleaving technique. It also overcomes the disadvantages of manual cleaving such as repeatability and accuracy.

LatticeAx 120

The samples can be cleaved with variations of thickness, size, and materials without compromising on the quality. Using this tool, the process can be completed in 2 minutes maximum time. To produce a fine and reproducible surface, précised knobs are used which is followed by a slow cleaving method. The accuracy is determined by the software and the scope you provide to it. It is combined with an optical microscope to improve the accuracy of the cleaving.

LatticeAx 225

The added high magnified imaging helps achieve accurate indenting. It results in a highly accurate cleaved sample. It is simple to operate and presents high quality and clean mirror finish. The workstation platform is robust in design for cleaving and indenting. The sample is secured with a vacuum pump with a pneumatic valve switch.

LatticeAx 420

The vision package comes with a 12X navitar zoom monocular microscope coupled with a 1600×1200 UXGA pixel color USB CCD camera with software of image display. It is a robust tool with fine/coarse focus.

The LatticeAx is one of the best tools known for its easy usage, accuracy, and repeatability. It can securely operate with gloved hands where there will not require handling the samples with bare fingers. There will require no screws, pins, and springs. It sure makes its mark in the industry for its perfection and easy usage feature.