Table of Contents

What is CNC Milling?

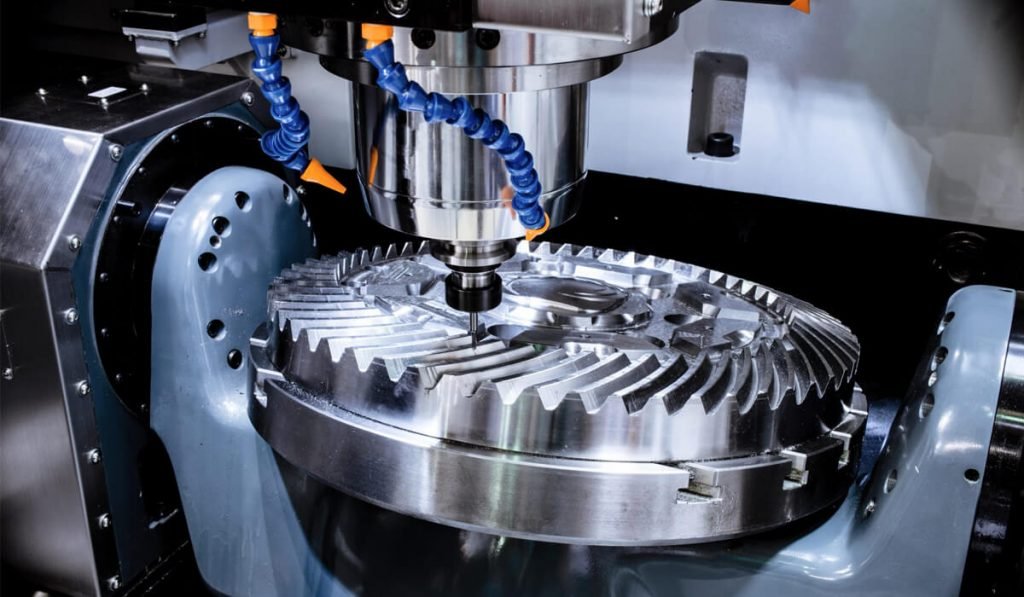

CNC Milling is the process of machining using computer controlled rotary cutters to remove material from a workpiece. It is a form of subtractive manufacturing and can create complex shapes and detailed parts.

The milling process can be divided into two main categories: face milling and peripheral milling. Face milling is the process of removing material from a face of a workpiece, while peripheral milling is removing material from the circumference of a workpiece.

CNC Milling machines are available in a variety of sizes and can create parts with dimensions of up to 60 inches (1524 mm) in length, width and height.

What Are the Benefits of CNC Milling?

There are several benefits to using CNC milling machines, including:

– Increased accuracy: CNC milling machines can create parts with high levels of accuracy. This is because the machines are controlled by computers, which can be programmed to create very precise movements.

– Increased productivity: CNC milling machines can produce parts very quickly. This is due to the fact that they are automated and can work for long periods of time without needing to be paused or stopped.

– Reduced waste: CNC milling machines can create parts such as custom sheet metal fabrication with very little waste material. This is because they only remove the material that is necessary to create the part.

– Increased flexibility: CNC milling machines can be used to create parts in a variety of materials, including metals, plastics, and composites. In addition, they can create features such as slots, pockets and recesses.

What Are the Different CNC Milling Machines?

There are several different types of CNC milling machines, including:

– Horizontal machining centers: Horizontal machining centers are the most common type of CNC milling machine. They are used to create parts that have horizontal surfaces, such as plates and blocks.

– Vertical machining centers: Vertical machining centers are used to create parts that have vertical surfaces, such as cylinders and cones.

– 5-axis machining centers: 5-axis machining centers are used to create parts that have complex shapes and curved surfaces. They can create parts in a variety of materials, including metals, plastics, and composites.

What Are the Different Milling Cutters?

Milling cutters are the tools that are used to remove material from a workpiece. There are several milling cutters, including:

– End mills: End mills are the most common type of milling cutter. They have cutting teeth at the end of the tool that is used to remove material from the workpiece.

– Ball end mills: Ball end mills have a rounded tip that is used to remove material from the workpiece.

– Face mills: Face mills are used to remove material from the face of a workpiece.

– T-slot cutters: T-slot cutters are used to create slots in a workpiece.

– Dovetail cutters: Dovetail cutters are used to create dovetails in a workpiece.

How Precise is CNC Milling?

CNC milling machines can create parts with top levels of accuracy. This is because they are controlled by computers, which can be programmed to create very precise movements. In addition, CNC milling machines have repeatability, which means that they can create identical parts over and over again.

What Materials Can be Machined Using a CNC Mill?

There’s a wide variety of materials that can be machined using a CNC mill. This includes metals (steel, aluminum, brass), plastics (acrylic, polycarbonate), composites (fiberglass, carbon fiber), and even wood. In addition, many different types of finishes can be applied to the machined parts, such as anodizing, powder coating with equipment like this, and plating.

How Long Does it Take to Produce a Part Using this Technology?

The time it takes to produce a part using CNC milling technology depends on a number of factors, including the complexity of the part, the material that is being machined, and the speed and accuracy of the CNC machine. In general, however, it takes much less time to produce a part using CNC milling than it does using traditional machining methods.

Conclusion

CNC milling machines are a versatile and efficient way to create parts. They can be used to create parts in a variety of materials, including metals, plastics, and composites. For this reason, many manufacturers are using CNC mills to create parts for their products. In addition, CNC milling machines are precision devices, which means that they can create parts with tight tolerances. Finally, CNC mills are controlled by computers, which allow for high flexibility and accuracy when machining parts.